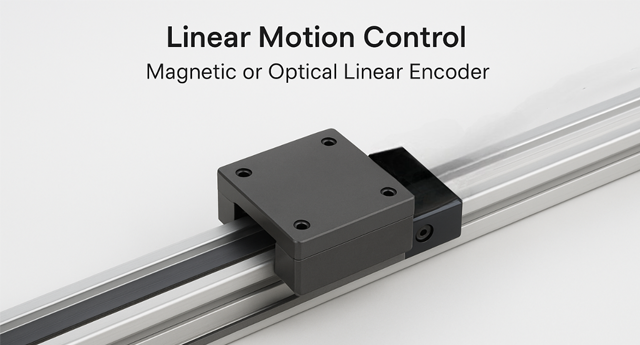

Linear Motion Control

Magnetic linear displacement sensor and optical linear encoder sensor play a vital role in achieving high-precision linear motion control. Widely applied in linear motors, linear motion modules, and linear stages, these non contact linear position sensor encoders deliver accurate position feedback essential for smooth, reliable, and repeatable motion. Whether in industrial automation, semiconductor manufacturing, or precision measurement systems, they ensure optimal performance, reduced errors, and enhanced productivity. By converting position into precise electronic signals, magnetic linear encoder sensor and optical linear displacement sensor enable advanced control systems to operate with exceptional accuracy—making them indispensable in modern high-performance linear motion solutions.

View All

Precision Rotary Motion Solutions

Magnetic & optical Rotary angle encoders with precision encoder disks are essential for high-accuracy rotary motion control. Widely used in direct drive (DD) motors, torque motors, rotary tables, indexing tables, and rotary stages, they provide precise angular position feedback for smooth, stable, and repeatable motion. These position sensor with encoder disc enable advanced control systems to achieve exceptional resolution and positioning accuracy, making them ideal for applications in CNC machining, semiconductor equipment, robotics, and automation. By ensuring exact rotational feedback, rotary ring encoders help maximize performance, improve efficiency, and deliver the precision demanded by today’s high-performance rotary motion solutions.

View All

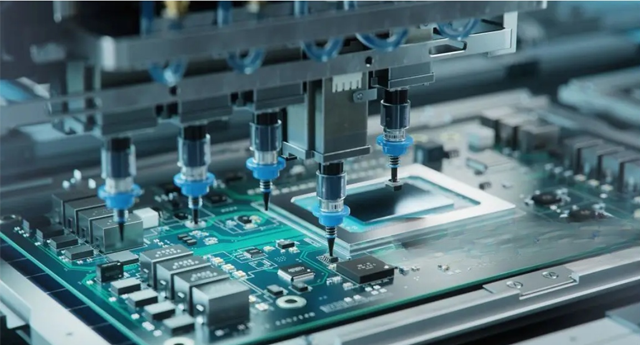

Semiconductor Manufacturing

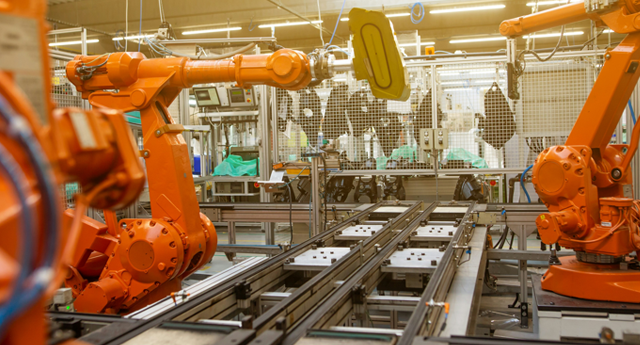

Magnetic position encoders and digital optical encoder are essential for precision automation in semiconductor manufacturing. Most manufacturers now rely on robots, rather than manual labor, to transport wafers—making automation a top operational priority. As a core component of these robotic systems, encoder repeatability is critical to maintaining efficiency and yield. Optical motion encoders deliver ultra-high, nanometer-level resolution, ensuring equipment operates with exceptional stability and precision over extended periods. Magnetic motor encoders offer robust performance in challenging environments, providing reliable feedback for smooth, repeatable motion. Together, they empower semiconductor production lines to achieve the accuracy, consistency, and reliability demanded by advanced chip manufacturing.

View All

New Energy Vehicles (NEV)

Magnetic and optical encoders are key to precision motion control in New Energy Vehicle (NEV) manufacturing. From battery cell assembly and module stacking to motor production and final vehicle testing, these encoders provide accurate position and speed feedback essential for high-efficiency automation. In robotic arms, conveyor systems, and precision welding equipment, they ensure smooth, repeatable motion for consistent product quality. Magnetic position sensor excel in harsh, dust-prone environments, while optical precision encoders deliver ultra-high resolution for demanding precision tasks. Together, they help NEV manufacturers achieve faster production, higher reliability, and the exacting standards required for next-generation electric mobility solutions.

View All

Lithium Battery Manufacturing

Magnetic scale encoder & optical grating encoders play a vital role in the precision automation of lithium battery manufacturing. From electrode coating, cell assembly, and module stacking to pack assembly and final inspection, these encoders provide accurate position and speed feedback for every stage. Optical optical shaft encoders deliver ultra-high resolution for processes requiring exact alignment, while magnetic digital encoder offer robust performance in dust-prone, vibration-heavy environments. By ensuring smooth, repeatable motion in robotic arms, conveyor systems, and welding equipment, they help manufacturers achieve higher efficiency, consistent quality, and long-term reliability—meeting the demanding standards of next-generation energy storage production.

View All

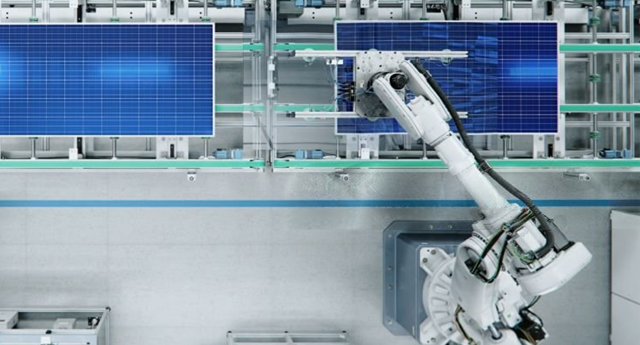

Photovoltaics (PV) Production

Magnetic encoder sensor and optical kit encoders are key enablers of precision automation in photovoltaics (PV) production. From silicon wafer slicing and cell processing to module assembly and final inspection, they deliver accurate position and speed feedback essential for high-efficiency manufacturing. Optical output encoders provide ultra-high resolution for delicate, alignment-critical steps, while magnetic ssi encoders excel in dust-prone, high-vibration environments common in PV fabrication. By ensuring smooth, stable, and repeatable motion in robotic handling, laser processing, and lamination systems, they help PV manufacturers boost productivity, maintain consistent quality, and meet the stringent performance standards required for today’s high-efficiency solar energy solutions.

View All

Automation & Robotics

At Hopo Technologies, we design high-performance magnetic strip encoder and optical encoders module that deliver uncompromising reliability for the most demanding robotics and automation applications.

Our optical industrial encoders provide sub-micron precision, making them ideal for surgical robots, semiconductor equipment, and laser processing systems. Our magnetic linear encoder sensor are built to perform in the toughest environments, from AGVs and exoskeletons to outdoor solar trackers—no cleanroom required.

Engineers choose us for reliable and cost-effective patented signal processing that eliminates jitter at high speeds, and maintenance-free designs that outlast the equipment they serve. From collaborative robots with advanced safety motion control, from ultra-fast pickers to precision stages for battery electrode inspection, our encoders set the standard for accuracy, durability, and performance.

View All

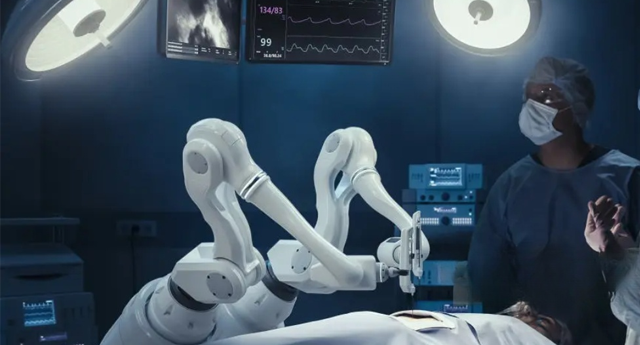

Medical Equipment

Magnetic position sensor and motor optical encoder are essential for precision motion control in today’s advanced medical equipment. From surgical robots and diagnostic imaging systems to laboratory automation and radiation therapy devices, they deliver accurate position and speed feedback that ensures smooth, reliable, and repeatable motion. Reflective optical encoder provide ultra-high resolution for applications demanding sub-micron precision, such as robotic surgery and high-definition imaging. Magnetic electric motor encoder offer robust performance in environments where dust, fluids, or vibrations are present, making them ideal for patient handling systems and rugged medical devices. Together, they help medical technology achieve the accuracy, safety, and consistency required for superior patient outcomes.

View All