Encoder Advantages: Why Encoders Are Essential in Modern Automation

In the era of smart manufacturing and industrial automation, encoders have become one of the most essential components driving precision and efficiency. These intelligent motion control devices play a vital role in converting mechanical motion into accurate digital signals, enabling real-time monitoring, positioning, and control across a wide range of automated systems. Understanding the encoder advantages is crucial for any engineer or manufacturer seeking to optimize performance, reduce downtime, and achieve higher operational accuracy.

From robotic arms and CNC machines to conveyor systems and servo motors, encoders deliver reliable feedback that ensures every motion is synchronized and efficient. Their ability to provide high-resolution position feedback, improve repeatability, and enhance safety makes them indispensable in modern industry. Unlike traditional sensors, encoders offer the dual benefits of speed and precision, making them a cornerstone technology in advanced motion control and automation applications.

As industries continue to evolve toward greater connectivity and intelligence, recognizing the benefits of encoders—including improved productivity, better energy efficiency, and superior control—helps companies stay competitive in the rapidly transforming manufacturing landscape. This article explores the key encoder advantages, different types of encoders, and how they are shaping the future of modern automation.

What Is an Encoder and How Does It Work?

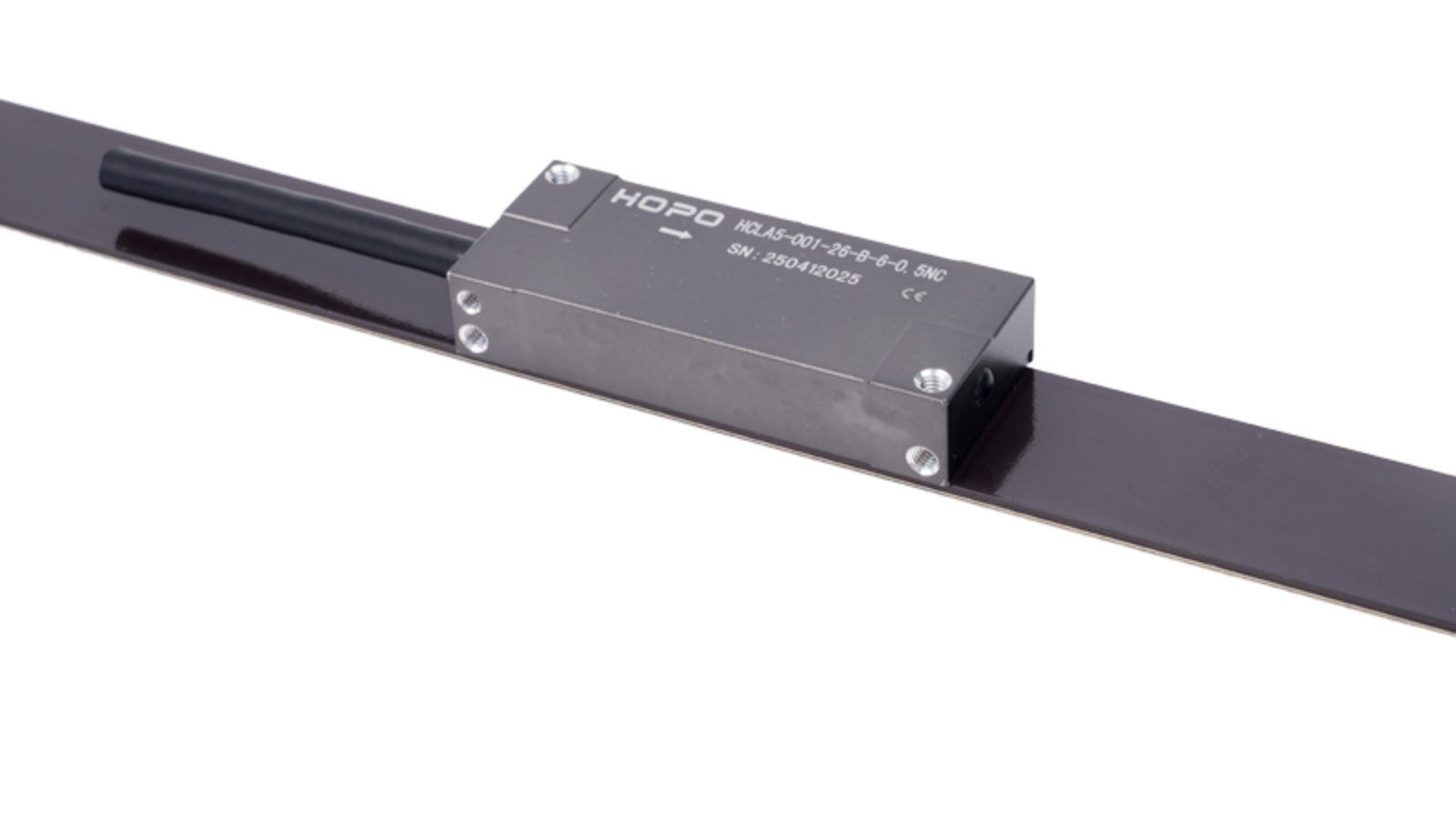

An encoder is a precision device used to convert mechanical motion—such as rotation or linear displacement—into electrical signals that can be interpreted by control systems. In modern automation, encoders play a vital role in providing accurate position and speed feedback, ensuring precise motion control and synchronization. There are several types of encoders, including rotary encoders, linear encoders, optical encoders, and magnetic encoders, each offering unique advantages depending on the application.

An optical encoder, for instance, uses a light source and photodetector to generate high-resolution signals ideal for clean environments, while magnetic encoders perform well in harsh industrial conditions. By translating movement into digital data, encoders enable machines, robots, and CNC systems to operate with remarkable accuracy and efficiency. Understanding how an encoder works is the first step toward optimizing automation performance and achieving greater reliability in motion control applications.

Core Encoder Advantages in Automation and Motion Control

Encoders play a vital role in modern automation and motion control systems by providing precise feedback and improving overall efficiency. One of the core encoder advantages is their ability to deliver high precision and accuracy in position and speed detection, which ensures smooth, consistent machine performance. Through real-time feedback, encoders allow closed-loop control systems to make instant adjustments, resulting in better synchronization and energy efficiency. Another major benefit is their reliability and durability—industrial encoders are designed to withstand vibration, dust, and harsh environments without compromising performance.

Additionally, their versatility makes them suitable for various applications, from robotics and CNC machines to conveyor systems and servo motors. By integrating encoders into automation processes, manufacturers can achieve higher productivity, minimize downtime, and maintain optimal operational accuracy. These encoder advantages make them an essential component for achieving precision-driven, efficient motion control across industrial systems.

Comparing Different Encoder Types: Which Offers the Most Advantages?

When evaluating the advantages of encoders for automation and motion control, it’s essential to understand how each encoder type performs under different operating conditions. The three most common types—optical encoders, magnetic encoders, and incremental vs. absolute encoders—each provide unique benefits that can significantly impact precision, reliability, and cost-efficiency.

-

Optical Encoder Advantages

Optical encoders are well known for their high resolution and accuracy, making them ideal for applications that demand precise motion control, such as CNC machines, robotic arms, and servo motor systems. They use light beams and photo detectors to generate clean, high-frequency signals, resulting in excellent repeatability and smooth performance. The main advantages of optical encoders include minimal signal noise, exceptional sensitivity, and superior positioning accuracy. However, they perform best in clean, controlled environments, as dust or oil contamination may affect signal clarity.

-

Magnetic Encoder Advantages

For industries that operate in harsh or dirty environments, magnetic encoders provide an excellent alternative. They rely on magnetic fields rather than light, which makes them highly resistant to dust, moisture, and vibration. The advantages of magnetic encoders include durability, low maintenance, and reliable performance even under extreme temperature variations. These encoders are widely used in automotive systems, elevators, and outdoor automation equipment, where long-term stability and resilience are crucial.

-

Incremental vs. Absolute Encoder Advantages

When comparing incremental encoders to absolute encoders, the difference lies in how position data is tracked and transmitted. Incremental encoders generate pulses to indicate movement, making them a cost-effective solution for applications where relative position feedback is sufficient. Their key advantage is simplicity and compatibility with most control systems. On the other hand, absolute encoders provide a unique position value for every shaft rotation, allowing for accurate position tracking even after power loss. This makes them ideal for robotics, servo systems, and safety-critical applications where consistent and error-free feedback is essential.

In summary, the most advantageous encoder type depends on the specific needs of your automation system. Optical encoders excel in high-precision environments, magnetic encoders shine in tough industrial conditions, and absolute encoders deliver superior reliability for continuous position tracking. By understanding these encoder advantages, engineers and manufacturers can select the ideal solution to enhance efficiency, accuracy, and control in any modern automation setup.

How Encoders Enhance Automation and Robotics Performance

Encoders play a pivotal role in modern automation and robotics, offering unmatched encoder advantages that improve precision, efficiency, and system reliability. By providing accurate real-time feedback, encoders enable robotic arms, conveyor systems, and automated guided vehicles (AGVs) to operate with precise motion control, minimizing errors and maximizing throughput. In servo motor applications, the benefits of encoders become even more apparent, as they allow for smooth acceleration, deceleration, and precise positioning, which is essential in high-speed assembly lines and CNC machinery.

Furthermore, encoders enhance automation performance by synchronizing multiple components, ensuring that every part of the system works in perfect harmony. Both optical encoders and magnetic encoders offer unique advantages for robotics, including high resolution, durability, and resistance to harsh industrial environments. Companies that integrate encoders into their robotics and automation solutions experience reduced downtime, higher product quality, and greater energy efficiency. Understanding and leveraging these encoder benefits is crucial for businesses aiming to optimize manufacturing processes and stay competitive in the era of smart factories and Industry 4.0.

Common Encoder Limitations and How to Overcome Them

While encoders provide numerous advantages in automation, understanding their common limitations is essential to maximize performance. One key limitation is sensitivity to environmental conditions. Optical encoders, for instance, may be affected by dust, dirt, or moisture, potentially reducing accuracy and reliability. Magnetic encoders, although more robust, can experience interference from strong electromagnetic fields, impacting signal quality. Another consideration is installation complexity. Improper alignment or mounting can lead to measurement errors, affecting overall system performance. Additionally, some encoders may have resolution or speed limitations, making them less suitable for high-precision or ultra-fast applications.

To overcome these challenges, selecting the right encoder type for the specific environment is critical. For dusty or wet conditions, sealed or IP-rated encoders are recommended. Regular maintenance and calibration ensure continued accuracy, while careful attention to alignment during installation minimizes mechanical errors. In cases where high-speed or ultra-precision is required, investing in high-resolution optical encoders or advanced absolute encoders can deliver superior results. By understanding these encoder limitations and applying practical solutions, engineers can fully leverage the advantages of encoders in modern automation systems.

How to Choose the Right Encoder to Maximize Advantages

Choosing the right encoder is essential to fully leverage encoder advantages in modern automation. When selecting an encoder, consider factors such as resolution, accuracy, environmental conditions, and output type. For high-precision applications, optical encoders often provide superior position feedback and repeatability, while magnetic encoders excel in harsh environments with dust, vibration, or moisture. Additionally, deciding between incremental and absolute encoders impacts both control accuracy and system reliability. Incremental encoders are ideal for applications requiring real-time motion feedback, whereas absolute encoders offer precise positional data even after power loss.

Evaluating your application's speed, torque, and environmental requirements ensures you maximize the benefits of encoder technology. By carefully considering these factors, you can select the most suitable encoder type, ensuring optimal performance, energy efficiency, and durability in your automation system. For professional guidance and tailored solutions, consult trusted encoder suppliers or industrial automation experts to match the best encoder to your system’s needs.

Conclusion: Maximize Your Automation Performance with Encoders

In conclusion, understanding encoder advantages is crucial for businesses aiming to optimize modern automation and achieve superior motion control accuracy. From providing real-time feedback to ensuring precision and reliability, encoders play an essential role in enhancing the performance of robotics, CNC machines, and industrial automation systems. By selecting the right encoder type—whether optical, magnetic, incremental, or absolute—you can fully leverage the unique benefits each offers, including durability in harsh environments, high resolution, and versatile applications across industries. Incorporating encoders into your automation strategy not only improves efficiency but also reduces downtime and maintenance costs, making your production lines smarter and more competitive. Don't miss out on the opportunity to maximize your operational performance and harness the full potential of encoder technology.

Ready to upgrade your automation systems with high-performance encoders? Contact our team today to find the perfect encoder solution tailored to your industrial needs and experience the full spectrum of encoder advantages.

-

Sep 04, 2025What Is a Rotary Encoder? A Complete Beginner’s Guide

Sep 04, 2025What Is a Rotary Encoder? A Complete Beginner’s Guide -

Sep 23, 2025Top 10 Optical Encoder Manufacturers in The World 2025

Sep 23, 2025Top 10 Optical Encoder Manufacturers in The World 2025 -

Oct 22, 2025Top 10 Absolute Encoder Manufacturers in The World 2025

Oct 22, 2025Top 10 Absolute Encoder Manufacturers in The World 2025 -

Sep 29, 2025Top 10 Linear Encoder Manufacturers in The World 2025

Sep 29, 2025Top 10 Linear Encoder Manufacturers in The World 2025