How Linear Encoders Work: Understanding the Working Principle

Linear encoders play a crucial role in modern industrial automation, providing precise position measurement and feedback for a wide range of machines and equipment. Understanding the linear encoder working principle is essential for engineers, technicians, and hobbyists who want to optimize performance in CNC machines, robotics, and high-precision manufacturing systems. In simple terms, a linear encoder converts the physical movement of a machine component into digital signals that can be accurately interpreted by controllers and software.

Whether you are curious about how a linear encoder works, the differences between optical and magnetic linear encoders, or their practical linear encoder applications, this guide will provide a clear and comprehensive overview. By exploring the working mechanism of linear encoders, their types, advantages, and common troubleshooting tips, you will gain the knowledge needed to select the right linear encoder for your application and ensure maximum accuracy and reliability.

Unlocking the secrets of linear encoders not only improves operational efficiency but also empowers you to make informed decisions when integrating these devices into complex automation systems.

What is a Linear Encoder?

A linear encoder is a precise measurement device used to detect and record the position of an object along a straight line. Understanding the linear encoder working principle is essential for anyone involved in industrial automation, robotics, CNC machines, or precision measurement systems. Unlike rotary encoders that track angular movement, linear encoders provide accurate linear position feedback, making them ideal for applications requiring high-resolution measurement.

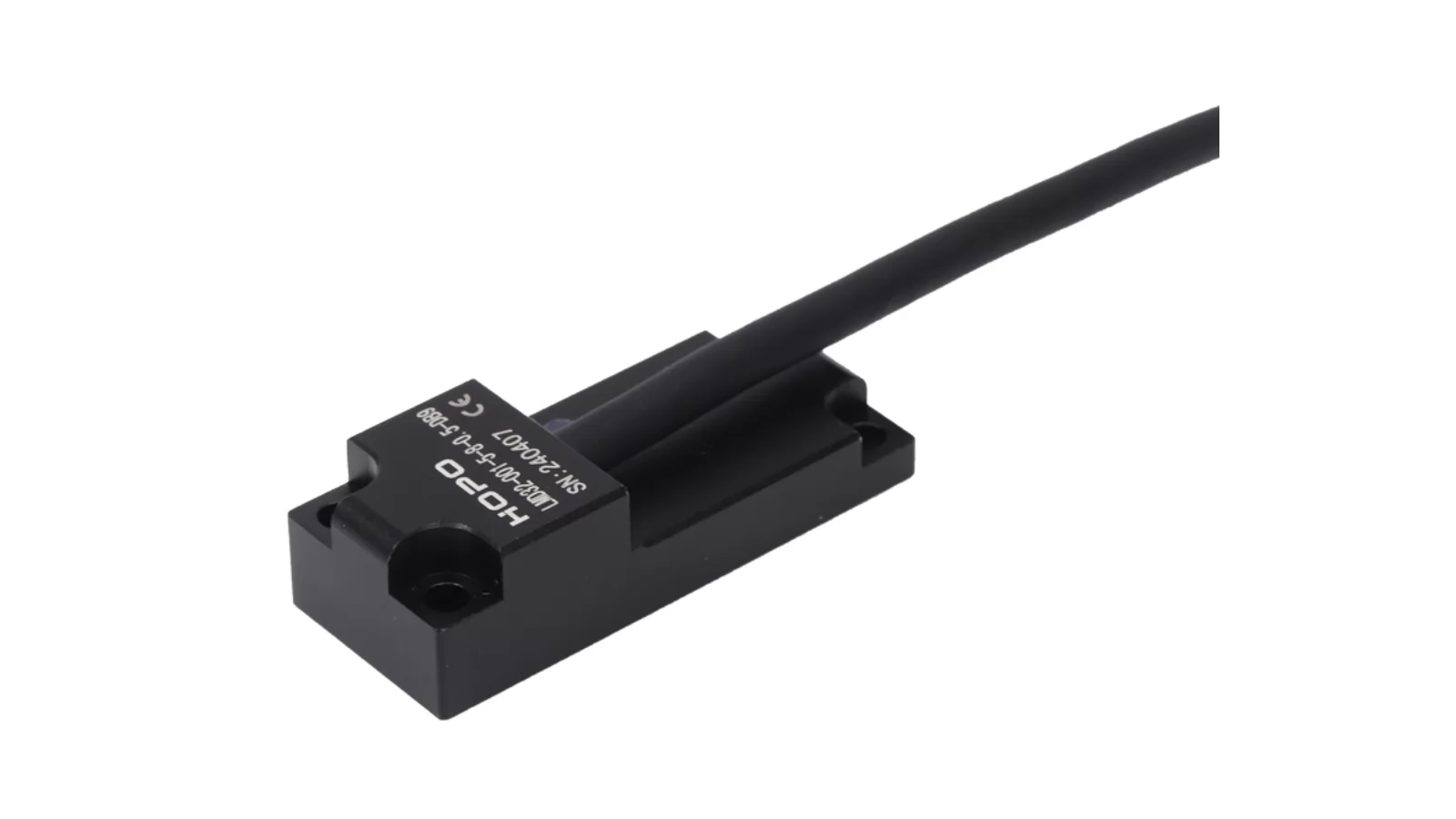

Linear encoders work by using a scale and a readhead, which interact to generate electrical signals that correspond to the object's position. These signals are then processed by electronics to deliver digital or analog output, allowing machines and control systems to perform precise movements. There are several types of linear encoders, including optical, magnetic, and capacitive encoders, each designed for specific environments and accuracy requirements.

In industrial settings, the applications of linear encoders are vast—from guiding CNC machine tools to monitoring robotics arms and ensuring precision in automated manufacturing. Understanding how a linear encoder works and its working mechanism helps engineers and technicians select the right encoder for their systems, optimize performance, and troubleshoot potential issues.

By mastering the fundamentals of linear encoder working principle, you can significantly improve measurement accuracy, system reliability, and operational efficiency in your automation projects.

Core Components of a Linear Encoder

A linear encoder is a precision measurement device, and understanding its core components is essential to grasp the linear encoder working principle. At the heart of every linear encoder are three critical elements: the scale, the readhead, and the electronic interface.

The scale, often made of glass, metal, or magnetic material, serves as the reference for position measurement. Its design directly impacts the linear encoder accuracy and resolution, making it a crucial consideration when choosing among different linear encoder types, such as optical or magnetic encoders.

The readhead is the sensor that moves along the scale, detecting positional changes and generating signals that represent the precise location. In optical linear encoders, the readhead uses light patterns to measure movement, while magnetic linear encoders rely on magnetic field variations. The readhead’s sensitivity and alignment are vital for ensuring consistent and reliable measurements.

Finally, the electronic interface processes the signals from the readhead, converting them into digital or analog outputs that machines can interpret. This interface is fundamental to achieving high precision in industrial automation, CNC machines, and robotics, all common applications of linear encoders.

Understanding these linear encoder components not only clarifies how a linear encoder works but also helps engineers select the right encoder for specific applications, ensuring optimal performance and accuracy.

How Linear Encoders Work: Step-by-Step

Understanding the linear encoder working principle is essential for anyone involved in precision measurement or industrial automation. At its core, a linear encoder converts physical movement into precise digital signals that machines can interpret. Here’s a step-by-step look at the linear encoder working mechanism.

-

Step 1: Signal Generation

The process begins with the linear encoder scale and readhead. As the scale moves relative to the readhead, it generates signals that represent position changes. Depending on the type of encoder, these signals can be incremental or absolute. Incremental encoders provide relative position data, while absolute encoders give a unique digital position for every point on the scale. Understanding how a linear encoder works at this stage is crucial for selecting the right type for your application.

-

Step 2: Signal Processing

Once the raw signals are generated, they are sent to the encoder’s electronics for processing. The encoder converts these pulses into readable digital output, often using quadrature signals to determine both direction and distance. This stage ensures that the movement is accurately captured, providing high-resolution feedback to control systems. By mastering this part of the linear encoder working mechanism, engineers can optimize performance in CNC machines, robotics, and other automation systems.

-

Step 3: Output Interpretation

Finally, the processed digital signals are transmitted to a controller or display, where they are interpreted as precise position or velocity data. This real-time feedback allows machines to perform accurate movements, ensuring efficiency and precision. Understanding how does a linear encoder work in this output phase helps in troubleshooting common issues and maintaining long-term accuracy.

By following these steps, you can clearly see the linear encoder working principle in action—from motion detection to digital output. Whether you are designing a high-precision machine or maintaining industrial equipment, knowing the linear encoder working mechanism is essential for achieving reliable and accurate performance.

Types of Linear Encoders and Their Applications

Linear encoders come in several types, each designed to meet specific measurement and automation needs. Understanding the types of linear encoders is crucial for selecting the right device for your application. The most common types include optical linear encoders, magnetic linear encoders, and capacitive linear encoders.

Optical linear encoders are known for their high precision and accuracy. They work by using a light source and a coded scale to detect position changes, making them ideal for applications requiring micron-level resolution, such as CNC machines, semiconductor manufacturing, and precision robotics. On the other hand, magnetic linear encoders offer robustness and resistance to dust, oil, and moisture, making them suitable for harsh industrial environments where durability is critical. These encoders are widely used in packaging machinery, factory automation, and heavy equipment.

Capacitive linear encoders provide a cost-effective solution for moderate-precision applications. They detect changes in capacitance between the readhead and the scale, making them suitable for compact devices, laboratory instruments, and mid-range industrial automation systems.

By choosing the right type of linear encoder, engineers can optimize system performance, enhance measurement reliability, and improve overall productivity. For example, optical linear encoders excel in high-precision tasks, while magnetic linear encoders ensure dependable operation in challenging environments. Understanding the linear encoder applications associated with each type helps businesses make informed decisions and select devices that match both technical requirements and budget constraints.

Common Issues and Troubleshooting

Even the most advanced linear encoders can encounter problems that affect their accuracy and performance. Understanding common linear encoder issues and how to troubleshoot them is essential for maintaining reliable measurement in industrial and automation applications. One frequent problem is signal loss, which can occur due to misalignment of the readhead or scale, excessive vibration, or electrical interference. To resolve this, ensure the encoder is properly mounted and all cables are securely connected, and check for potential sources of electromagnetic interference.

Another typical issue involves accuracy degradation. Over time, dirt, dust, or oil on optical scales can reduce a linear encoder’s precision. Regular cleaning and maintenance, using appropriate cleaning materials, can prevent this problem. For magnetic encoders, strong external magnetic fields may interfere with the signal, so shielding or relocating the encoder may be necessary.

Linear encoder troubleshooting also often addresses mechanical misalignment or wear. Misaligned components can cause inconsistent readings or intermittent operation. Carefully recalibrating the encoder and ensuring the mechanical system is within tolerance can restore accurate performance. Additionally, monitoring the encoder’s output signal using a diagnostic tool or software can help detect subtle errors before they become critical.

By proactively addressing these common linear encoder issues, users can ensure optimal performance, extend the lifespan of their equipment, and maintain precise feedback for CNC machines, robotics, and other high-precision applications. For detailed guidance on linear encoder troubleshooting and maintenance, consider consulting the manufacturer’s manual or technical support resources.

Advantages of Understanding the Working Principle

Understanding the linear encoder working principle provides significant benefits for engineers, technicians, and automation specialists. By knowing how linear encoders work, professionals can select the right type of encoder—whether optical, magnetic, or capacitive—to achieve maximum precision and reliability in their applications. One of the key linear encoder advantages is improved accuracy: understanding the signal generation and processing ensures precise position feedback in CNC machines, robotics, and industrial automation systems.

Moreover, a solid grasp of the working principle helps in troubleshooting common issues such as signal loss, misalignment, or interference, allowing for quicker maintenance and reduced downtime. It also enables better customization of encoder installation and alignment for specific operational conditions, enhancing overall system efficiency. Finally, understanding how linear encoders work empowers users to make informed decisions on scale selection, resolution requirements, and environmental suitability, maximizing the performance and lifespan of the equipment.

In short, the advantages of understanding the linear encoder working principle extend beyond mere knowledge—they translate into higher operational precision, reduced errors, and optimized industrial performance, making this understanding essential for anyone working with modern measurement and automation systems.

FAQs About Linear Encoders

Q1: What is a linear encoder and how does it work?

A linear encoder is a precision measurement device used to detect position, speed, or displacement in industrial machines. The linear encoder working principle involves a readhead scanning a scale (optical, magnetic, or capacitive) to generate electronic signals, which are then processed to provide accurate position feedback. This mechanism is essential in CNC machines, robotics, and other automation systems.

Q2: What are the main types of linear encoders?

There are several types of linear encoders, including optical linear encoders, magnetic linear encoders, and capacitive linear encoders. Each type has unique advantages: optical encoders offer high precision, magnetic encoders are robust in harsh environments, and capacitive encoders provide cost-effective solutions for compact applications.

Q3: How accurate are linear encoders?

Linear encoder accuracy depends on the type of encoder, resolution, environmental conditions, and proper alignment. Optical encoders can achieve sub-micron accuracy, while magnetic encoders provide reliable performance in dust-prone or high-vibration environments. Understanding accuracy specifications is crucial when selecting a linear encoder for critical applications.

Q4: Where are linear encoders commonly used?

Linear encoder applications span multiple industries. They are widely used in CNC machining, industrial automation, robotics, semiconductor manufacturing, and measurement systems. Any application that requires precise position or motion feedback can benefit from a linear encoder.

Q5: How do I troubleshoot a linear encoder?

Linear encoder troubleshooting often involves checking signal quality, alignment, and environmental factors such as dust or vibration. Common issues include signal loss, misalignment, or interference. Regular maintenance, proper installation, and choosing the right type of encoder for the application can prevent most problems.

Q6: What is the difference between incremental and absolute linear encoders?

Incremental encoders generate relative position signals and require a reference point after power-up, while absolute encoders provide a unique digital code for every position, allowing immediate position reading. Choosing the right type depends on the application's precision requirements and system design.

Conclusion

In conclusion, understanding the linear encoder working principle is essential for anyone seeking precise measurement and accurate position feedback in modern industrial applications. From optical to magnetic and capacitive linear encoders, each type offers unique advantages and performance characteristics tailored to specific needs. By mastering how linear encoders work—including signal generation, processing, and output interpretation—you can optimize machinery performance, improve automation accuracy, and ensure reliable operation in diverse environments. Whether you are looking for high-resolution linear encoders for CNC machines or robust encoders for harsh industrial settings, choosing the right encoder based on accuracy, resolution, and application requirements is crucial.

Ready to enhance your systems with precise and reliable linear encoders? Explore our complete range of linear encoders today and find the perfect solution to meet your industrial automation needs. Contact us now to get expert guidance and a tailored recommendation!

-

Sep 04, 2025What Is a Rotary Encoder? A Complete Beginner’s Guide

Sep 04, 2025What Is a Rotary Encoder? A Complete Beginner’s Guide -

Sep 23, 2025Top 10 Optical Encoder Manufacturers in The World 2025

Sep 23, 2025Top 10 Optical Encoder Manufacturers in The World 2025 -

Oct 22, 2025Top 10 Absolute Encoder Manufacturers in The World 2025

Oct 22, 2025Top 10 Absolute Encoder Manufacturers in The World 2025 -

Sep 29, 2025Top 10 Linear Encoder Manufacturers in The World 2025

Sep 29, 2025Top 10 Linear Encoder Manufacturers in The World 2025