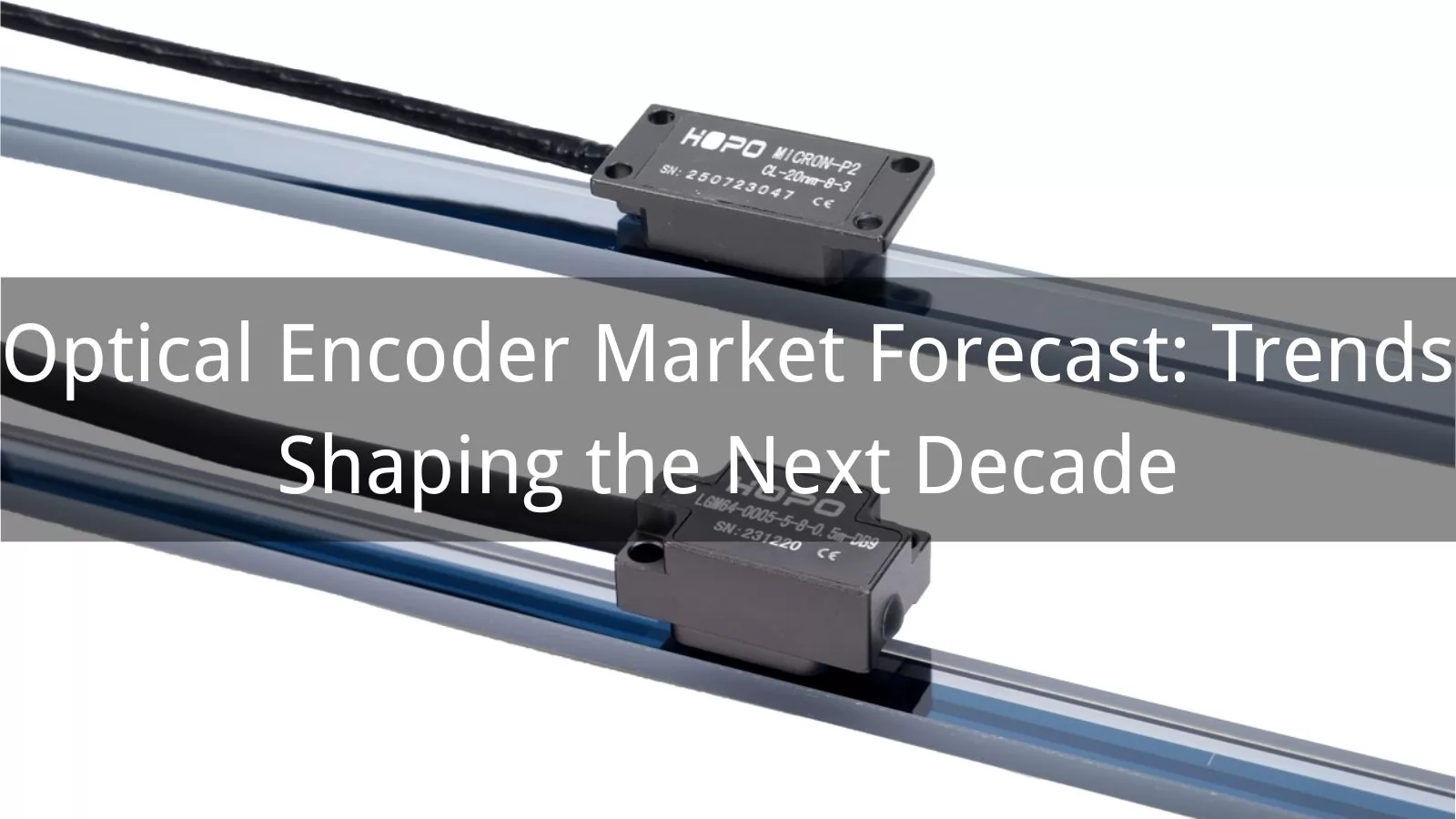

Optical Encoder Market Forecast: Trends Shaping the Next Decade

The global optical encoder market is entering a transformative decade marked by rapid technological innovation and unprecedented demand across automation, robotics, electric vehicles, and semiconductor manufacturing. As industries accelerate their transition toward smarter, more precise motion-control systems, the need for high-resolution and ultra-reliable optical encoders continues to surge. According to recent optical encoder market forecasts, the sector is expected to experience strong, sustained growth driven by Industry 4.0 adoption, expanding robotic automation, and rising investment in precision equipment.

Understanding the trends shaping the optical encoder industry outlook over the next ten years is essential for engineers, OEMs, system integrators, and decision-makers planning long-term strategies. From breakthroughs in encoder technology to shifting regional demand and evolving competitive landscapes, the coming decade will redefine how optical encoders support next-generation industrial performance. This article provides a comprehensive, data-driven forecast designed not only to enhance your market insight but also to support high-visibility SEO performance, ensuring the content ranks prominently while delivering valuable, actionable information for readers.

Overview of the Global Optical Encoder Market (2025–2035)

The global optical encoder market is entering a period of accelerated expansion, driven by the rapid adoption of automation, advanced robotics, and high-precision motion control across multiple industries. According to recent optical encoder market forecasts, the sector is projected to experience strong and sustained growth from 2025 to 2035, with the market size expected to increase significantly as manufacturers worldwide modernize production systems and integrate smarter motion-feedback solutions. Analysts predict that the market will maintain a healthy CAGR, fueled by ongoing investments in Industry 4.0, semiconductor manufacturing, electric vehicles, and medical technology—all of which rely heavily on high-resolution and reliable encoder systems.

Growth will be most notable in regions leading technological innovation, such as Asia-Pacific, North America, and Europe, where demand for precision automation continues to rise. Countries like China, Japan, and South Korea are expected to dominate production and consumption due to their robust industrial bases and expanding robotics ecosystems. At the same time, North America’s strong automation adoption and Europe’s advanced automotive and machine-tool sectors will further support global market growth.

However, the outlook is not without challenges. The optical encoder market faces pressure from fluctuating raw material costs, the rise of competing technologies such as magnetic encoders, and supply chain uncertainties affecting electronic components. Despite these hurdles, industry analysts agree that the long-term demand for optical encoders will remain strong, supported by continuous technological advancements and the industry’s shift toward digitalized, data-driven manufacturing. As a result, the period from 2025 to 2035 represents one of the most promising growth phases the optical encoder industry has seen in decades.

Technology Trends Transforming the Optical Encoder Market

As the optical encoder market continues to expand, several breakthrough optical encoder technology trends are reshaping how manufacturers design motion-control systems for robotics, automation, and precision machinery. One of the most significant developments is the widespread adoption of high-resolution optical encoders, which deliver ultra-precise feedback needed for semiconductor equipment, collaborative robots, and advanced CNC machines. At the same time, miniaturization is accelerating, with compact encoder designs becoming essential for medical devices, drones, and lightweight robotic joints.

Another major trend is the rise of smart optical encoders equipped with built-in diagnostics, real-time monitoring, and IoT connectivity—features that enable predictive maintenance and improve equipment uptime. Additionally, manufacturers are enhancing durability by developing encoders with better dust resistance, vibration tolerance, and IP-rated housings, making them suitable for harsh industrial environments. Together, these innovations are transforming the future of the optical encoder market and setting new performance standards across every major industry.

Market Trends by Encoder Type: Incremental vs. Absolute

As the optical encoder market evolves, the demand trajectory for incremental encoders and absolute encoders is beginning to show distinct patterns based on application requirements, technology advancements, and long-term industry developments.

Growing Preference for Absolute Encoders in High-Precision Applications

The absolute encoder market is projected to experience faster growth over the next decade, driven by industries that require high-resolution, real-time position feedback. Advanced robotics, medical devices, semiconductor equipment, and electric vehicle systems increasingly rely on absolute optical encoders because they provide unique position values after power loss and superior accuracy in multi-turn or complex motion profiles. As automation becomes more intelligent and safety-focused, manufacturers are shifting toward absolute encoders for their reliability and ability to meet stringent performance standards.

Stable and Strong Demand for Incremental Encoders in Industrial Automation

Despite the rise of absolute technologies, the incremental encoder market remains resilient—especially within traditional industrial automation sectors. Packaging lines, conveyor systems, CNC machinery, and general motion-control applications continue to favor incremental optical encoders due to their cost efficiency, simplicity, and high-speed performance. Many factories worldwide still operate legacy systems designed around incremental feedback, ensuring consistent and ongoing demand across OEMs and retrofit projects.

Which Encoder Type Will Dominate the Next Decade?

While absolute encoders are expected to capture a larger share of high-precision, high-value applications, incremental encoders will maintain dominance in cost-sensitive and high-speed environments. The forecast suggests a clear dual-growth landscape, where both encoder types thrive—absolute encoders leading innovation-driven sectors, and incremental encoders sustaining broad adoption across mainstream industrial automation. Businesses entering the next decade of digital manufacturing must evaluate their application requirements carefully, balancing performance, budget, and long-term scalability when selecting between incremental and absolute encoder technologies.

Key Industry Sectors Shaping Optical Encoder Demand

The optical encoder market is undergoing rapid expansion, driven by several high-growth industry sectors that increasingly rely on precision motion control, real-time feedback, and reliable positioning systems. As demand for high-resolution optical encoders accelerates, a few key industries stand out as the primary engines of global market growth.

1. Robotics & Cobots: The Fastest-Growing Robotics Encoder Market

Robotics remains the strongest catalyst for rising optical encoder demand, especially with the widespread adoption of industrial robots, collaborative robots (cobots), and autonomous mobile robots (AMRs/AGVs). Optical encoders play a foundational role in joint control, speed feedback, navigation, and safe human-robot interaction, making them indispensable for next-generation robot designs. As manufacturers seek higher accuracy and smoother motion profiles, the robotics encoder market is forecast to achieve double-digit growth throughout the next decade.

2. Industrial Automation & Smart Manufacturing

Driven by Industry 4.0, the demand for industrial automation encoders continues to surge. Optical encoders are essential in CNC machinery, packaging lines, conveyors, semiconductor fabrication tools, precision inspection equipment, and other automated systems. Their ability to deliver real-time, ultra-precise feedback supports predictive maintenance and high-efficiency production workflows. As factories modernize and integrate more intelligent systems, industrial automation will remain one of the largest consumers of optical encoder technology.

3. Electric Vehicles (EVs) & Automotive Systems

The automotive sector—especially electric vehicles—has become a major contributor to global optical encoder market growth. Encoders are widely used for EV motor control, battery assembly lines, steering systems, ADAS sensors, and dynamic stability technologies that require high reliability and accuracy. As EV production ramps up and automotive electronics become more sophisticated, EV motor encoders and high-precision rotary feedback systems will see exponential demand.

4. Aerospace, Defense & Medical Equipment

High-precision environments such as aerospace, defense, and medical devices rely heavily on ultra-reliable optical encoders. In these sectors, encoders support applications like surgical robotics, imaging equipment, satellite systems, missile guidance, and avionics where even the smallest error margin is unacceptable. The increasing adoption of advanced motion-control technologies ensures that these industries remain strong contributors to long-term optical encoder demand.

Regional Forecast: Where the Optical Encoder Market Will Grow the Fastest

The global optical encoder market is entering a decade of rapid geographic diversification, with growth driven by automation, robotics, and electric vehicle manufacturing. While mature regions will continue to lead in innovation, the fastest-growing optical encoder markets will emerge in Asia-Pacific and select developing economies. Understanding regional dynamics is essential for manufacturers, distributors, and OEMs building long-term strategies.

Asia-Pacific (China, Japan, South Korea): The World's Fastest-Growing Optical Encoder Market

Asia-Pacific will remain the dominant force in the optical encoder market forecast, expanding faster than any other region due to large-scale industrial automation, semiconductor fabrication, and robotics deployment. China leads in production capacity and cost-effective encoder solutions, while Japan and South Korea drive innovation in high-precision encoders for electronics, robotics, and machine tools. The region’s strong EV manufacturing base further accelerates demand for motor feedback and motion-control encoders.

North America: Strong Growth Driven by Robotics and Industrial Automation

North America is positioned for steady expansion as the adoption of AMRs, warehouse automation technologies, and high-end robotics increases. The United States—home to leading automation integrators and aerospace manufacturers—continues to invest heavily in advanced optical encoder technologies for motion control, precision manufacturing, and defense applications. Government incentives supporting reshoring and smart factories contribute to the rising demand.

Europe: Stable Expansion Fueled by Automotive and Machine Tool Sectors

Europe shows consistent growth in optical encoder demand, driven by Germany’s advanced machine tool industry and strong automotive innovation across countries like Germany, France, and Sweden. As European manufacturers transition toward electrification, digitalization, and Industry 5.0, optical encoders play a crucial role in ensuring precision and reliability. The region maintains high standards for accuracy and efficiency, supporting increased adoption of absolute and high-resolution encoders.

Emerging Markets (India, ASEAN, Middle East): New Opportunities for Encoder Manufacturers

India and ASEAN markets are becoming attractive growth hubs as companies expand into local manufacturing and infrastructure development projects. These regions’ investments in robotics, EV assembly, and renewable energy create new opportunities for cost-competitive encoder suppliers. Meanwhile, Middle Eastern nations are accelerating their smart manufacturing and logistics initiatives, contributing to rising demand for industrial encoders and automation components.

Market Opportunities for Manufacturers & Importers

The next decade presents significant market opportunities for optical encoder manufacturers and importers, driven by accelerating automation, advanced robotics, and the global shift toward electrification. As industries demand increasingly precise motion-control solutions, suppliers who can innovate and scale will be well-positioned to capture a growing share of the global optical encoder market.

One of the most promising opportunities lies in industrial automation retrofitting, where factories replace outdated feedback systems with high-resolution optical encoders to improve efficiency, reduce downtime, and enable predictive maintenance. Manufacturers offering compact, durable, and high-accuracy encoder solutions can directly benefit from this long-term upgrade cycle.

Another fast-growing segment is robotics, particularly collaborative robots (cobots), AGVs, and AMRs. These systems rely on high-precision optical encoders for joint feedback, navigation, and motion safety. As global robot installations continue to rise, encoder suppliers who provide miniaturized designs and smart encoder technologies with real-time diagnostics will see expanding demand.

The electric vehicle (EV) sector also represents a major opportunity for encoder importers and OEMs. Optical encoders are increasingly used in EV motors, battery assembly equipment, and automated inspection systems. With EV production expected to surge through 2035, the demand for reliable feedback components will scale correspondingly.

Furthermore, emerging markets—including India, Southeast Asia, and the Middle East—are investing heavily in smart manufacturing, opening new distribution channels for encoder importers. Local system integrators are seeking cost-competitive yet high-performance encoder options, giving both established brands and rising suppliers a chance to expand internationally.

For companies able to deliver customization, fast lead times, and strong technical support, the next decade offers an exceptional window to strengthen their position in the optical encoder market and build long-term partnerships with automation, robotics, and EV manufacturers worldwide.

Challenges & Risks to Watch in the Next Decade

As the optical encoder market accelerates toward 2035, several challenges and risks could influence growth trajectories and disrupt global supply chains. One of the most significant threats is raw material and semiconductor shortages, which continue to pressure production timelines and raise manufacturing costs. Additionally, increasing competition from magnetic encoders and low-cost sensor alternatives may limit market share growth in cost-sensitive industries. The market also faces rising concerns around intellectual property protection, particularly as more emerging players enter the optical encoder industry with similar product designs and technologies.

Another critical challenge is the lack of standardization across global markets, creating compatibility issues for OEMs that rely on multi-vendor encoder systems. Environmental demands—including the need for higher durability, better sealing, and improved resistance to dust, heat, and vibration—will further push manufacturers to innovate. Collectively, these risks highlight the importance for suppliers and buyers to stay aware of evolving encoder market challenges, strengthen supply chain strategies, and invest in resilient, future-ready technologies to remain competitive over the next decade.

Conclusion: Prepare for the Future of the Optical Encoder Market

As global automation accelerates and precision-driven industries continue to expand, the optical encoder market is entering one of its most transformative decades. From robotics and electric vehicles to semiconductor manufacturing and advanced medical devices, the next generation of innovation will rely heavily on high-accuracy motion feedback systems. By understanding the key trends highlighted in this optical encoder market forecast, businesses can anticipate shifts in technology, supply chain dynamics, and end-user demand—and position themselves at the forefront of rapid industry growth.

Looking ahead, opportunities will emerge across high-resolution optical encoders, smart encoder technologies, compact designs, and solutions tailored for harsh industrial environments. Companies that proactively adopt these advancements will gain a decisive competitive edge, while those that hesitate may struggle to keep pace with global market leaders.

Now is the time to strengthen your strategy.

Whether you are an OEM, system integrator, distributor, or engineering team, preparing for the future of the optical encoder market means partnering with suppliers who understand technological evolution and can deliver reliable, high-performance solutions.

Stay ahead of the curve as the next decade reshapes encoder technology. Contact our team today to explore cutting-edge optical encoder solutions, gain expert insights, or request tailored guidance based on your application needs. Equip your business with the precision, reliability, and innovation required to thrive in a rapidly evolving global market.

-

Sep 04, 2025What Is a Rotary Encoder? A Complete Beginner’s Guide

Sep 04, 2025What Is a Rotary Encoder? A Complete Beginner’s Guide -

Sep 23, 2025Top 10 Optical Encoder Manufacturers in The World 2025

Sep 23, 2025Top 10 Optical Encoder Manufacturers in The World 2025 -

Oct 22, 2025Top 10 Absolute Encoder Manufacturers in The World 2025

Oct 22, 2025Top 10 Absolute Encoder Manufacturers in The World 2025 -

Sep 29, 2025Top 10 Linear Encoder Manufacturers in The World 2025

Sep 29, 2025Top 10 Linear Encoder Manufacturers in The World 2025