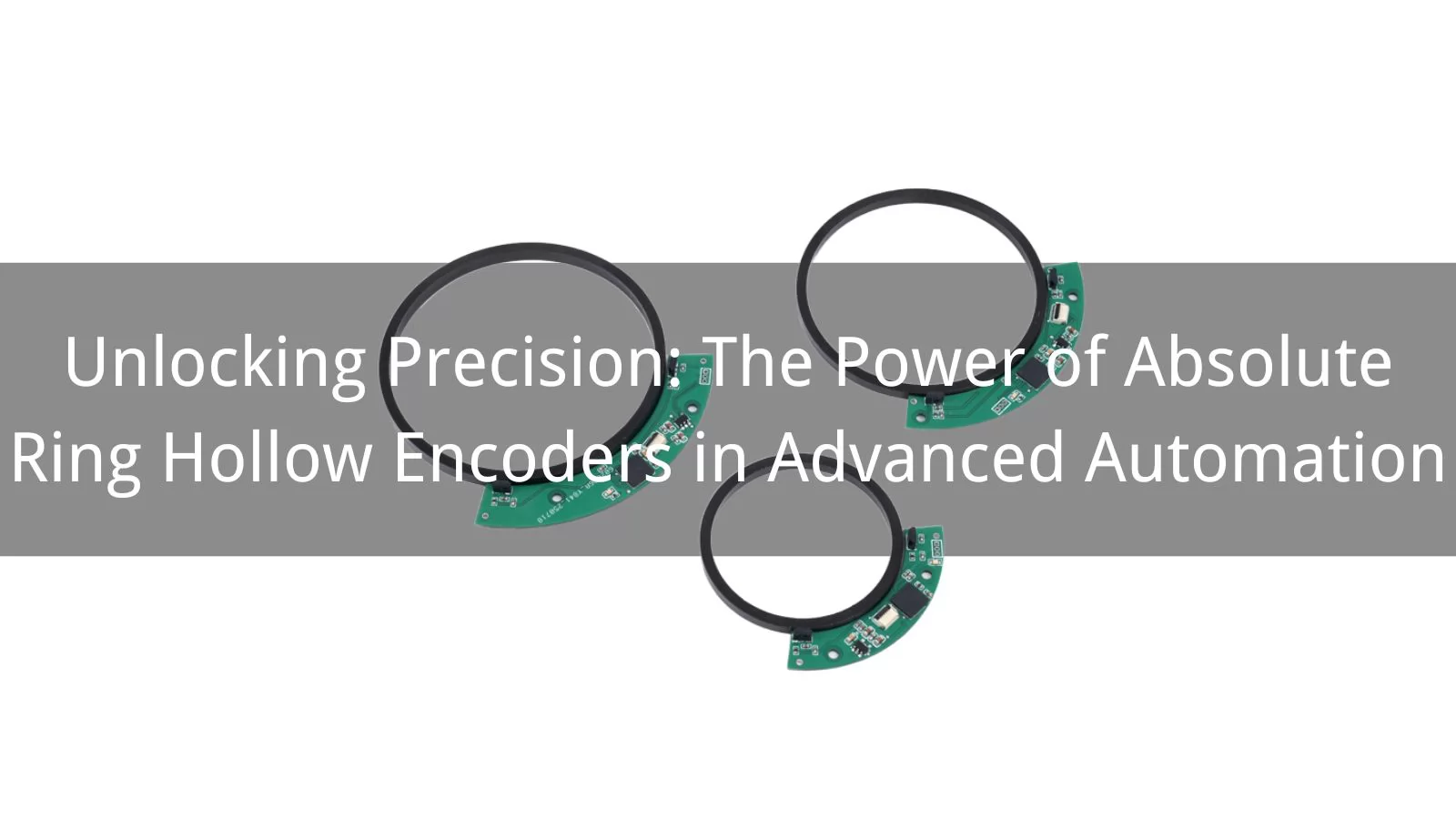

Unlocking Precision: The Power of Absolute Ring Hollow Encoders in Advanced Automation

In the relentless pursuit of precision, reliability, and efficiency within high-end industrial and automation equipment, engineers constantly seek advanced sensing solutions. Among these, the Absolute Ring Hollow Encoder stands out as a critical component, primarily utilized for accurately measuring rotational angles, positions, and speeds.

At its core, this encoder provides a unique, one-to-one digital code corresponding to a specific position within a full 360° rotation. The most significant advantage? Upon power-up, it instantly communicates its absolute position to the system without requiring a "homing" or "referencing" sequence to a mechanical origin. This "power-on-and-know" capability is a game-changer for complex machinery.

An absolute hollow type ring encoder (often called a hollow-shaft absolute ring encoder or absolute magnetic ring encoder) is a position feedback device designed to measure rotational angle or position directly on a rotating shaft or ring, with an absolute position output rather than incremental pulses.

Where Absolute Ring Hollow Encoders Make a Difference

Let's explore the diverse applications where these encoders are indispensable:

CNC Machine Tools / Machining Centers:

-

Used for: Spindle orientation, tool changer mechanisms, and rotary tables (e.g., 4th and 5th axes).

-

Function: Ensures the spindle stops at precise angles for tool changes and controls the accurate indexing of rotary tables for complex surface machining.

Industrial Robots & Cobots:

-

Used in: Each joint of the robot (the "shoulder," "elbow," "wrist," etc.), for joint angle detection in articulated arms or rotary axes.

-

Function: Provides real-time absolute angle feedback for each joint, forming a closed-loop control system that ensures the robot's end-effector moves to pre-programmed positions with high precision and repeatability.

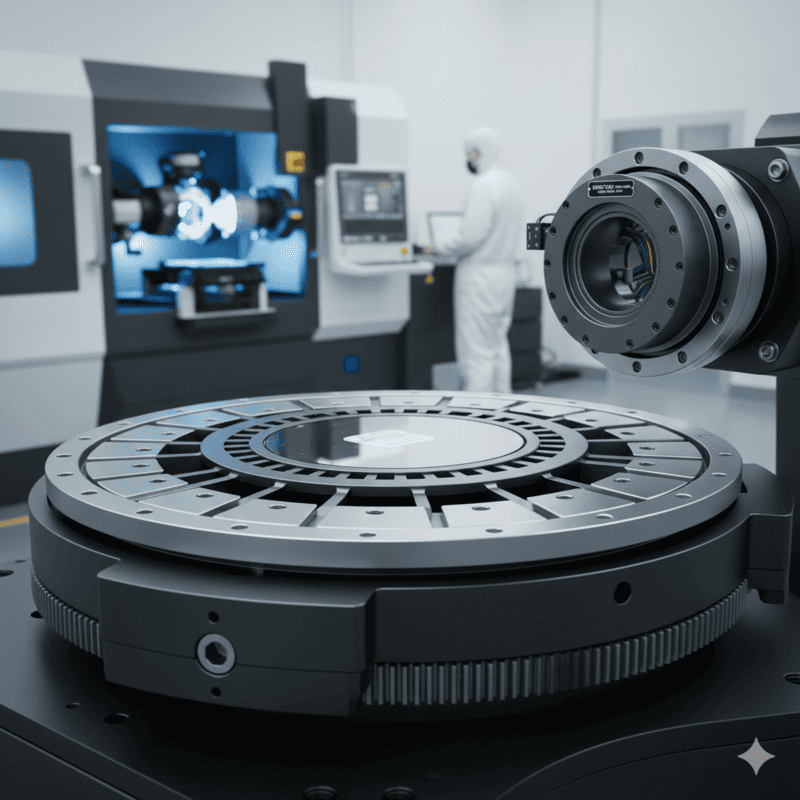

Precision Turntables and Indexing Tables:

-

Used in: Measurement equipment, semiconductor manufacturing equipment (e.g., lithography machines), and precision assembly lines.

-

Function: Achieves extremely high-precision angular positioning and indexing, such as rotating by fixed, minute angles.

Radar and Antenna Systems:

-

Used for: Pitch and azimuth axes of military radar and satellite communication antennas.

-

Function: Accurately feeds back the antenna's pointing angle, enabling precise target tracking and locking.

Medical and Semiconductor Equipment:

-

Used in: Rotary gantry of CT scanners, robotic arms of radiotherapy equipment (Gamma Knife, CyberKnife), and for compact, high-precision rotary motion sensing.

-

Function: Ensures absolute positional accuracy for imaging and treatment, which is paramount for patient safety.

High-End Servo Motors & Direct Drive Motors:

-

Used as: An integral part at the rear of many high-performance servo motors, directly connected to the motor shaft, providing integrated position feedback without mechanical couplers.

-

Function: Provides high-resolution absolute position feedback to the servo drive, enabling precise torque, speed, and position control.

Wind Turbines & Rotating Platforms: Shaft angle measurement even after power loss.

Usage / Working Principle

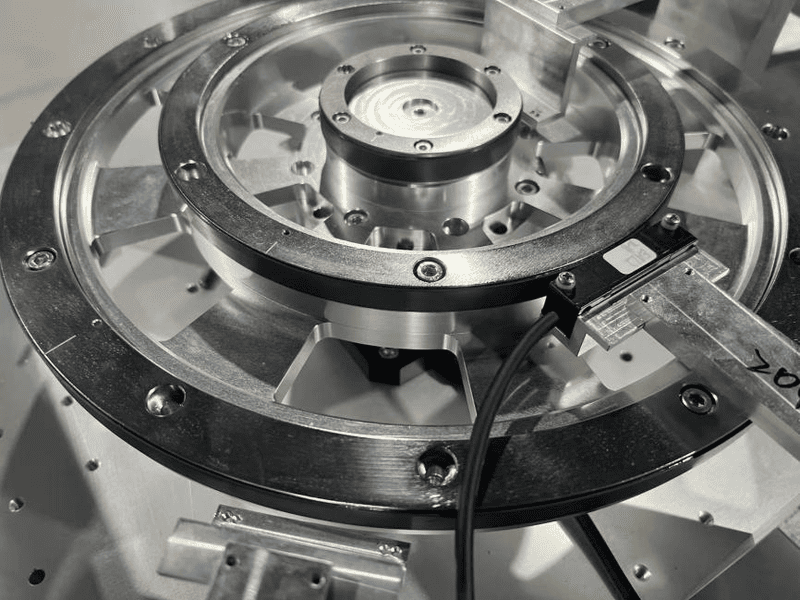

The absolute ring hollow encoder's operation is elegantly simple yet highly effective:

-

The hollow ring is mounted directly onto a shaft, bearing, or rotor (no coupling needed).

-

A stator or readhead (sensor head) is fixed on the stationary part, reading the absolute position of the ring.

-

The encoder ring has coded tracks (optical or magnetic) corresponding to absolute angular positions.

-

Output is digital absolute position data (e.g., SSI, BiSS-C, Tamagawa, Panasonic, MODBUS).

-

Once powered on, it immediately provides the exact angular position — no homing or reference run needed.

For details, please check the video: https://youtu.be/IAC7Gk6mKbY

The Undeniable Advantages of Hollow Absolute Ring Encoders

Compared to traditional incremental encoders and other absolute encoder structures, absolute ring hollow encoders offer significant advantages:

| Feature | Advantage |

|---|---|

| Hollow structure | Enables direct mounting around shafts or through cables, pipes, or rotary joints — saves space and simplifies design. |

| Absolute position | Reports true position immediately at power-up — no need for calibration or homing. |

| Compact & lightweight | Ideal for compact robotic joints or integrated drives. |

| No mechanical coupling | Reduces backlash, misalignment issues, and mechanical wear. |

| High accuracy & resolution | Optical types offer up to arcsecond-level precision; magnetic types are robust with micrometer-level accuracy. |

| Robust against vibration/dust | Especially magnetic versions — suitable for harsh industrial environments. |

| Maintenance-free | Non-contact design means no wear over time. |

| High Rigidity and Stability | The ring structure is typically mounted securely to the equipment via flanges or screws, forming a robust mechanical unit. This design offers excellent vibration and shock resistance, maintaining long-term measurement stability. |

| Strong Anti-Interference Capability | Outputs digital or serial data, less susceptible to electrical noise than pulse signals, ensuring greater reliability in complex industrial environments. |

In Summary

An absolute hollow type ring encoder is ideal for modern compact motion systems needing:

-

Direct-on-shaft installation.

-

Reliable absolute angular data.

-

Low profile and non-contact measurement.

-

Robust performance in dynamic or harsh environments.

It's especially popular in robot joints, direct-drive motors, and integrated servo systems, where traditional shaft-type encoders are too bulky or need extra couplings.

Looking for a High-Performance Absolute Ring Encoder? Consider Hopo Tech

As a solo manufacturer of absolute ring encoders in China, Hopo Tech provides a comprehensive selection of ring sizes to meet diverse customer needs. Our outer diameters range from 82mm to 450mm, offering resolutions up to 2 arc seconds. Hopo Tech's specifications compete directly with leading global brands like RLS and Heidenhain, but at a significantly more competitive pricing, making high-precision automation more accessible.

Contact us to learn how our advanced solutions can elevate your machinery.

-

Sep 04, 2025What Is a Rotary Encoder? A Complete Beginner’s Guide

Sep 04, 2025What Is a Rotary Encoder? A Complete Beginner’s Guide -

Sep 23, 2025Top 10 Optical Encoder Manufacturers in The World 2025

Sep 23, 2025Top 10 Optical Encoder Manufacturers in The World 2025 -

Oct 22, 2025Top 10 Absolute Encoder Manufacturers in The World 2025

Oct 22, 2025Top 10 Absolute Encoder Manufacturers in The World 2025 -

Sep 29, 2025Top 10 Linear Encoder Manufacturers in The World 2025

Sep 29, 2025Top 10 Linear Encoder Manufacturers in The World 2025