What Are Encoders Used For in Industrial Applications? Explained Simply

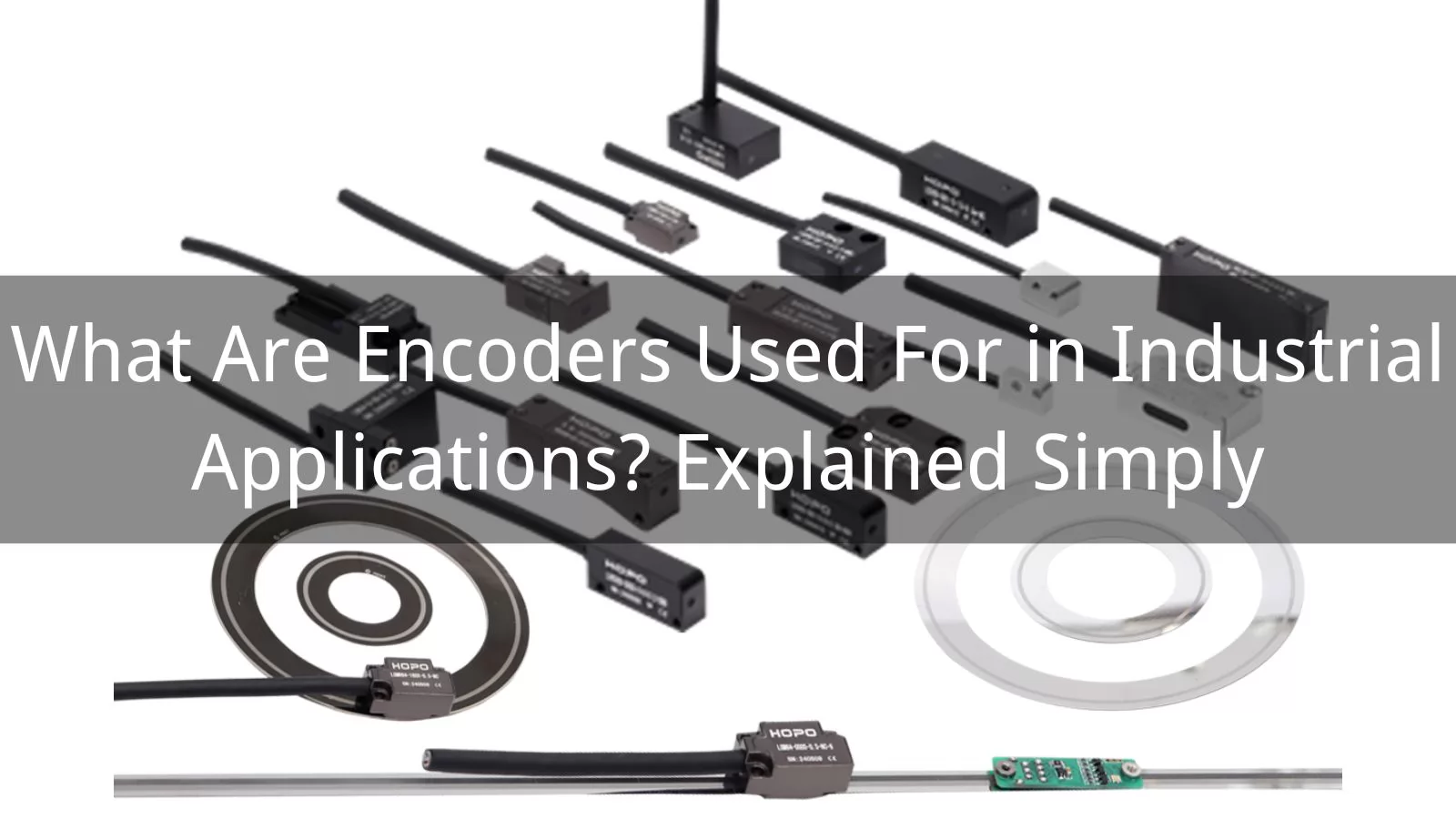

Encoders play a critical role in modern industrial automation, acting as essential devices that convert motion into precise digital signals. By providing accurate position and speed feedback, encoders are widely used in applications such as robotics, CNC machines, packaging lines, medical equipment, and renewable energy systems. In industrial environments where efficiency, accuracy, and reliability are vital, encoders ensure smooth operation, improved productivity, and consistent quality control.

Whether optical or magnetic, incremental or absolute, encoders help manufacturers optimize performance and reduce downtime in demanding conditions. Understanding what encoders are used for in industrial applications allows businesses to select the right technology for their specific needs, from high-speed production lines to harsh, dust-prone environments. In this guide, we will explain encoders simply, highlight their benefits, and explore why they are indispensable across multiple industries.

What Is an Encoder? A Simple Definition

An encoder is a sensor or device that converts motion, position, or speed into digital signals for precise control in machines and automation systems. In simple terms, encoders provide accurate feedback that allows industrial equipment to operate with efficiency and reliability. They are widely used in robotics, CNC machines, packaging lines, and medical devices, ensuring smooth motion control and high productivity.

Whether incremental or absolute, optical or magnetic, encoders play a vital role in industrial automation by translating physical movement into data that can be monitored and optimized. Understanding what an encoder is and what encoders are used for helps businesses choose the right solution for their specific industrial applications.

How Encoders Work: The Basics

Encoders work by converting mechanical motion—such as rotation or linear movement—into electrical signals that can be read by control systems. In industrial applications, these signals provide essential feedback on speed, position, and direction, allowing machines to achieve precise motion control. Optical encoders use light sensors to detect movement with high accuracy, while magnetic encoders rely on magnetic fields for durability in harsh environments.

Whether in robotics, CNC machinery, or packaging lines, encoders ensure efficiency, accuracy, and reliability. Understanding how encoders work is the foundation for choosing the right encoder type—incremental or absolute—for your specific industrial needs.

Key Industrial Applications of Encoders

Encoders are widely used in industrial applications to deliver precision, speed, and reliability. In robotics and motion control, they provide accurate positioning for smooth operations. In CNC machines and manufacturing, encoders ensure high accuracy and repeatable performance. Industries like packaging and printing rely on encoders for speed synchronization, while medical devices demand their safety and reliability.

Even in renewable energy systems such as wind turbines and solar tracking, encoders optimize efficiency. By enhancing accuracy and control, industrial encoders play a vital role in improving productivity across automation, robotics, and advanced manufacturing.

Benefits of Using Encoders in Industrial Applications

- Improved Accuracy and Precision

Encoders in industrial applications provide real-time position and speed feedback, ensuring machines operate with high accuracy. This precision reduces errors in CNC machines, robotics, and packaging lines, helping manufacturers achieve consistent product quality and minimizing costly rework.

- Enhanced Productivity and Efficiency

Industrial encoders boost efficiency by synchronizing motion control across automated systems. They allow robotics, conveyors, and printing machines to run faster with fewer interruptions. This improved workflow increases production output, reduces downtime, and maximizes ROI for manufacturers.

- Better Quality Control and Consistency

Encoders are used in industrial processes to maintain strict quality standards. By providing reliable motion feedback, they help ensure uniform product dimensions, accurate labeling, and smooth operation in high-speed manufacturing. This consistency strengthens customer trust and reduces defective output.

- Reliability in Harsh Environments

Industrial encoders are designed to perform reliably in dust, vibration, or temperature-sensitive conditions. Magnetic encoders, for example, excel in heavy-duty environments where optical encoders may fail. This durability ensures continuous operation and reduces maintenance costs in critical industrial systems.

- Cost Savings and Reduced Downtime

Using encoders in automation systems lowers maintenance costs by preventing unexpected failures. Real-time monitoring allows early detection of performance issues, minimizing machine downtime. Over time, this reliability translates into significant cost savings, making encoders a valuable investment in industrial automation.

Choosing the Right Encoder for Your Application

Selecting the right industrial encoder is essential for ensuring accuracy, reliability, and efficiency in automation. When deciding what encoder to use, consider factors such as operating environment, resolution, speed, and load capacity. For harsh conditions, magnetic encoders offer durability, while optical encoders deliver higher precision in clean environments.

Incremental encoders are ideal for speed and direction feedback, whereas absolute encoders provide exact positioning for robotics, CNC machines, and medical devices. Matching the encoder type to your industry needs improves performance and minimizes downtime. Whether in packaging, renewable energy, or manufacturing, choosing the right encoder ensures long-term reliability and productivity.

Common Challenges and Solutions with Industrial Encoders

- Dust and Contaminants

In industrial environments, encoders often face dust, oil, and debris that reduce accuracy and reliability. Using magnetic encoders or sealed housings ensures stable performance, making them ideal for harsh industrial applications.

- Vibration and Mechanical Stress

Heavy machinery causes vibration and shock that can shorten the lifespan of optical encoders. To solve this, industries rely on ruggedized industrial encoders with reinforced bearings and shock-resistant designs for long-term durability.

- Electrical Noise Interference

Factories with motors and drives create electrical noise that disrupts encoder signals. Employing differential signal transmission and shielded cables helps maintain accurate encoder feedback, ensuring smooth automation and precise motion control.

- High-Speed Operation

In CNC machines and robotics, high RPMs can cause signal loss or lag in incremental encoders. Selecting high-resolution encoders with faster response rates guarantees reliable motion feedback and accuracy in demanding industrial applications.

- Maintenance and Downtime

Frequent recalibration or cleaning of encoders leads to production downtime. Choosing maintenance-free absolute encoders with non-contact designs reduces wear, ensures consistent performance, and lowers the total cost of ownership in automation systems.

Conclusion: Why Encoders Are the Backbone of Modern Industry

Encoders are essential in industrial applications, powering automation, robotics, CNC machines, and renewable energy systems with unmatched accuracy and reliability. By delivering precise motion feedback, encoders improve efficiency, reduce downtime, and ensure consistent quality across production lines. Whether using incremental or absolute encoders, industries rely on them for optimized performance and long-term stability.

Choosing the right encoder for your application can transform operations, making encoders the true backbone of modern industry. Looking for high-performance industrial encoders? Contact us today to find the best solution for your needs.

-

Sep 04, 2025What Is a Rotary Encoder? A Complete Beginner’s Guide

Sep 04, 2025What Is a Rotary Encoder? A Complete Beginner’s Guide -

Sep 23, 2025Top 10 Optical Encoder Manufacturers in The World 2025

Sep 23, 2025Top 10 Optical Encoder Manufacturers in The World 2025 -

Oct 22, 2025Top 10 Absolute Encoder Manufacturers in The World 2025

Oct 22, 2025Top 10 Absolute Encoder Manufacturers in The World 2025 -

Sep 29, 2025Top 10 Linear Encoder Manufacturers in The World 2025

Sep 29, 2025Top 10 Linear Encoder Manufacturers in The World 2025