What Is a Linear Encoder and How Does It Work?

In today's precision-driven industries, understanding what a linear encoder is is essential for achieving accurate motion control. Linear encoders play a crucial role in CNC machines, robotics, and automation systems, converting linear movement into precise digital signals.

This guide explains how linear encoder technology works, its types, and practical applications, helping engineers and technicians choose the right solution for high-performance and reliable measurement.

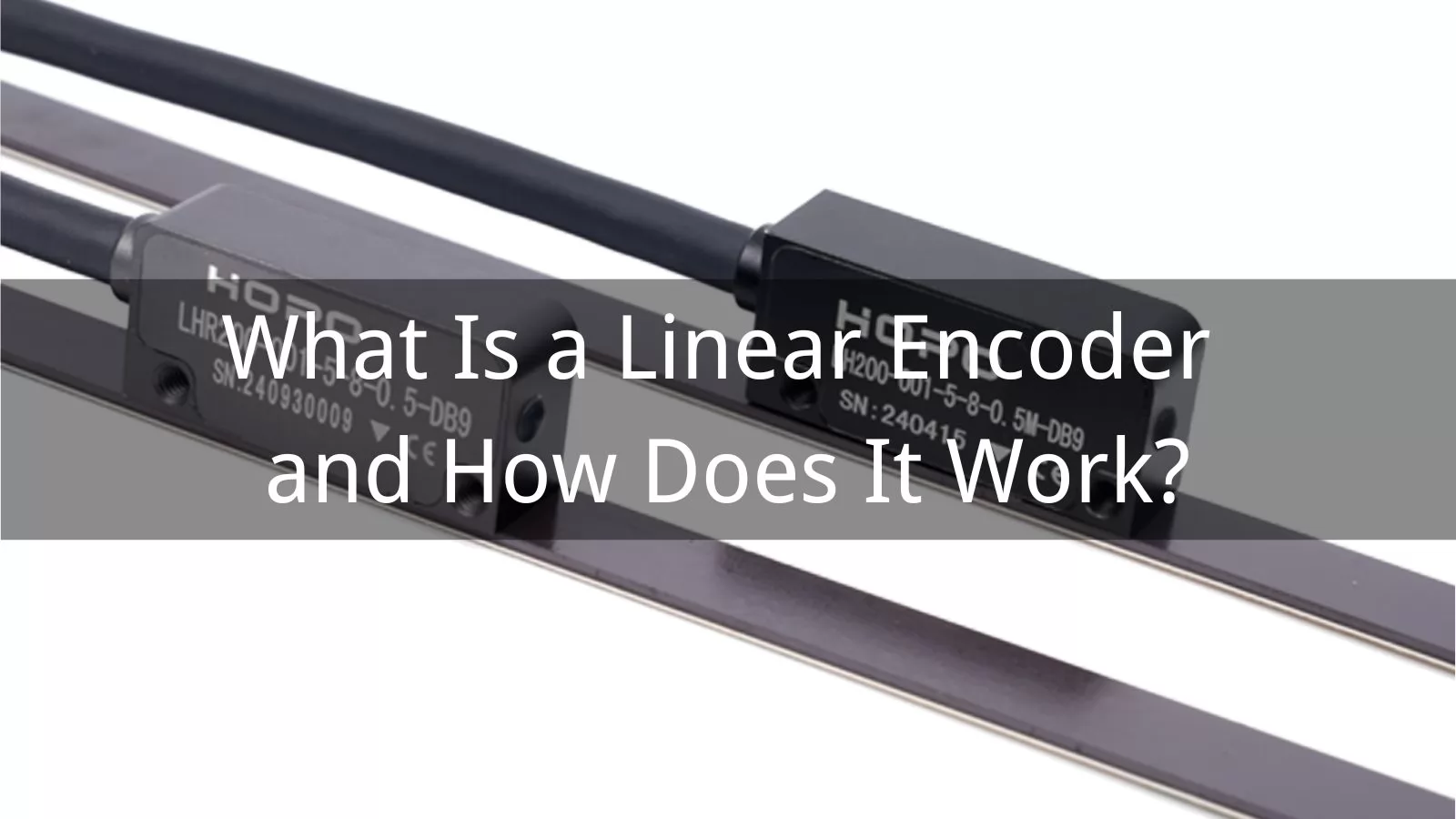

What Is a Linear Encoder? Definition and Basics

A linear encoder is a precision device that measures linear displacement and converts it into an electronic signal for accurate position tracking. Widely used in CNC machines, robotics, and automation systems, linear encoders ensure high-precision motion control and reliable measurements.

Understanding the definition and basics of linear encoders helps engineers select the right type—optical, magnetic, or capacitive—for their specific applications, improving efficiency, accuracy, and overall system performance.

How Does a Linear Encoder Work?

A linear encoder works by precisely measuring linear displacement, converting motion into readable electronic signals. Using technologies like optical linear encoders, which detect light patterns, or magnetic linear encoders, which sense magnetic fields, these devices ensure high accuracy in motion control. The readhead scans the scale or track, sending signals to a controller that calculates exact positions, making them ideal for CNC machines, robotics, and automation systems.

Understanding how linear encoders work helps engineers select the right type—incremental or absolute—for their applications, ensuring reliable performance, precise measurements, and seamless integration into industrial setups.

Key Components of a Linear Encoder System

A linear encoder system consists of several essential components that ensure precise position measurement and reliable performance. The scale or graduated track serves as the reference, available in absolute or incremental formats, while the readhead detects movement along this scale with high accuracy. The interface and signal processing unit then converts this motion into digital or analog output for integration with CNC machines, robotics, or automation systems.

Additional components, such as mounting brackets and protective covers, help maintain stability and prevent environmental interference. Understanding these linear encoder components is crucial for selecting the right system, ensuring long-term accuracy, and optimizing performance in high-precision industrial applications.

Types of Linear Encoders

- Incremental Linear Encoder

Incremental linear encoders measure relative movement by generating pulses as the scale moves. They are ideal for CNC machines and automation systems where precise position tracking is required. Keywords: incremental linear encoder, linear encoder types.

- Absolute Linear Encoder

Absolute linear encoders provide exact position data for each point along the scale, even after power loss. They are widely used in robotics, semiconductor equipment, and high-precision applications. Keywords: absolute linear encoder, linear encoder applications.

- Optical Linear Encoder

Optical linear encoders use light-based sensors for high-resolution and precise measurements. They are preferred in industries requiring extreme accuracy, such as medical devices and CNC machinery. Keywords: optical linear encoder, linear encoder technology.

- Magnetic Linear Encoder

Magnetic linear encoders detect position through magnetic fields, offering robustness in harsh environments. They are commonly used in industrial automation and outdoor applications. Keywords: magnetic linear encoder, linear encoder industrial use.

- Capacitive and Inductive Linear Encoder

These encoders rely on electric field or inductive changes to measure linear movement. They are suitable for specialized applications where traditional optical or magnetic encoders may face limitations. Keywords: capacitive linear encoder, inductive linear encoder.

Applications of Linear Encoders

Linear encoders are essential for industries that demand precise position measurement and high-accuracy motion control. Common applications include CNC machines, where linear encoder CNC systems ensure exact tool positioning, and robotics, where they enable smooth and precise movement. In automation systems, linear encoders for automation monitor linear displacement to optimize efficiency and reliability.

They are also widely used in semiconductor manufacturing, medical devices, and high-precision laboratory equipment, where accuracy and repeatability are critical. Choosing the right type of linear encoder—optical, magnetic, or absolute—can significantly enhance performance across these applications. Explore how integrating a high-quality linear encoder can elevate precision, productivity, and reliability in your industrial processes.

Advantages and Limitations

Linear encoders offer unmatched precision and reliability, making them ideal for CNC machines, robotics, and industrial automation. Their high-resolution measurement and durability ensure consistent performance in demanding environments. Optical linear encoders provide exceptional accuracy, while magnetic and inductive types excel in harsh conditions.

However, linear encoders can be sensitive to dust, vibration, and extreme temperatures, requiring careful installation and maintenance. Cost may also be higher compared to simpler measurement devices. Understanding these advantages and limitations helps engineers and automation specialists choose the right linear encoder for their specific applications, ensuring optimal motion control and long-term efficiency.

How to Choose the Right Linear Encoder

Selecting the right linear encoder is crucial for achieving precise motion control in your applications. Consider key factors such as accuracy, resolution, environmental conditions, and interface compatibility. Optical linear encoders offer high precision for clean environments, while magnetic encoders perform reliably in harsh industrial settings. Decide between incremental and absolute encoders based on whether relative or exact positioning is required.

Evaluating these aspects ensures you choose a linear encoder that meets your performance needs, enhances system efficiency, and reduces downtime. Explore our expert guide to selecting the best linear encoder and optimize your automation projects today.

FAQ Section (Targeting Long-Tail Keywords)

Q1: What is the difference between a linear encoder and a rotary encoder?

A linear encoder measures straight-line motion, while a rotary encoder tracks rotational movement. Understanding this distinction helps you choose the right encoder for your CNC machines, robotics, or automation systems.

Q2: How accurate are linear encoders?

Linear encoders offer high precision, often down to micrometer-level resolution, making them ideal for industrial automation, CNC machining, and laboratory equipment where exact positioning is critical.

Q3: Can linear encoders operate in harsh industrial environments?

Yes. Many modern linear encoders are designed to withstand dust, vibration, and temperature variations. Selecting a magnetic or sealed optical linear encoder can enhance durability in tough conditions.

Q4: Which industries benefit most from linear encoders?

Industries like CNC machining, robotics, semiconductor manufacturing, and medical device production rely heavily on linear encoders for precise motion control and high-efficiency automation.

Q5: How do I calibrate a linear encoder for optimal performance?

Proper calibration ensures accurate readings. Follow the manufacturer’s guidelines for scale alignment, readhead positioning, and signal verification to maintain the best linear encoder performance over time.

Conclusion

In conclusion, a linear encoder is an essential device for achieving precise linear displacement measurement in CNC machines, robotics, and industrial automation. Understanding how a linear encoder works, its types, and proper maintenance ensures high-precision performance and long-lasting reliability.

Explore our range of high-precision linear encoders today to enhance your automation projects and achieve superior motion control.

-

Sep 04, 2025What Is a Rotary Encoder? A Complete Beginner’s Guide

Sep 04, 2025What Is a Rotary Encoder? A Complete Beginner’s Guide -

Sep 23, 2025Top 10 Optical Encoder Manufacturers in The World 2025

Sep 23, 2025Top 10 Optical Encoder Manufacturers in The World 2025 -

Oct 22, 2025Top 10 Absolute Encoder Manufacturers in The World 2025

Oct 22, 2025Top 10 Absolute Encoder Manufacturers in The World 2025 -

Sep 29, 2025Top 10 Linear Encoder Manufacturers in The World 2025

Sep 29, 2025Top 10 Linear Encoder Manufacturers in The World 2025