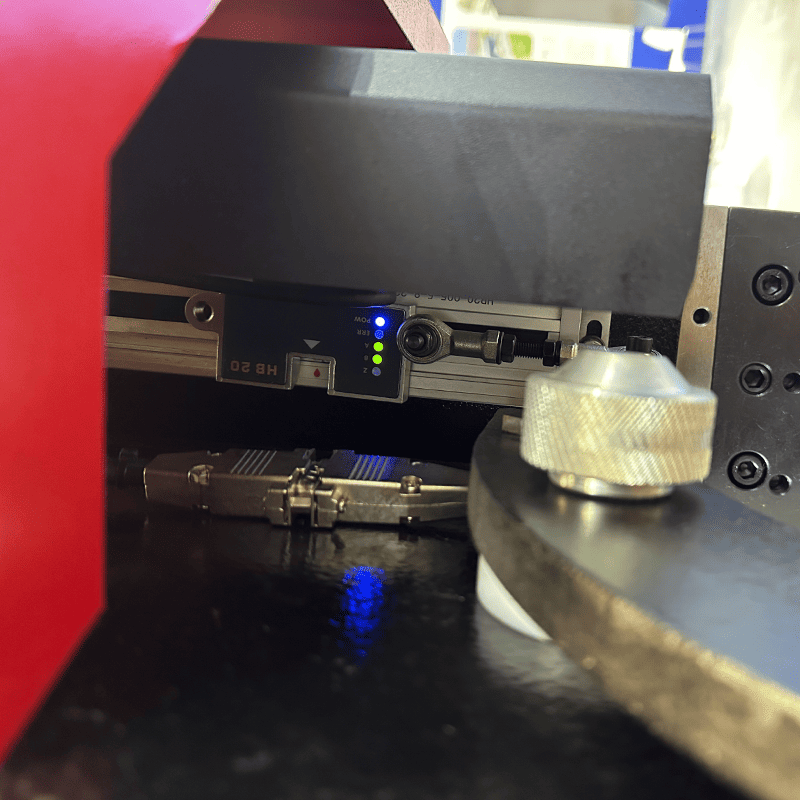

HB20 Enclosed Incremental Magnetic Linear Encoder

- Resolution options: 1 μm or 5 μm

- Multiple high-precision origin signals for flexible referencing

- Non-contact inductive sensing for wear-free operation

- Excellent vibration resistance and durable mechanical structure

- LED signal indicators for quick status monitoring

- Wide voltage input/output support

- High contamination resistance for harsh workshop conditions

- High-precision bearing ensures smooth, particle-free operation

- Ultra-flexible drag chain cable (10+ million bend cycles)

- Multiple cable options: NC bare wire, DB9, DB15, or custom configurations